CORE SYSTEM

"CORE SYSTEM" is the Japanese patented laser scanner which can inspect some surface of Si Wafer, CMP/Grinding Surface, Thin Films, Spattered Surface, Resin Coated Surface, Hard Disk and LCD/ FPD, etc. with high speed laser.

technology of "CSM"

Applications

Thin Films,Spattered Surface, Resin Coated Surface, Silicon Wafer, Hard Disk & Glass Disk /Mask, FPD, Metallic Film, CMP Surface, Dia Turn Surface, Grinding Surface

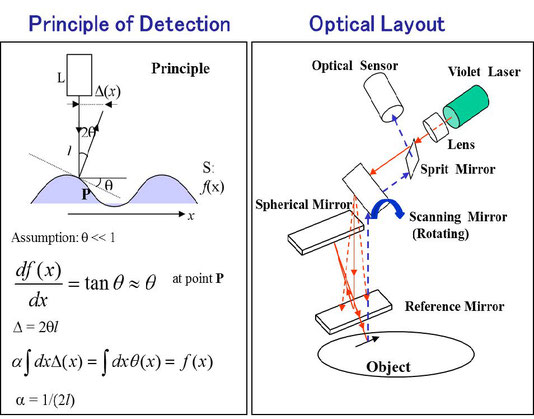

“Detection principle” The laser is applied to the measurement surface, the angle of the catoptric light changes with the gradient angle of the surface. Because proportion (gradient angle two times) makes this reflective second of arc angle of dip in the surface, when angle displacement (minute angle 2 θ = ⊿(x)) is measured, derivative value in a sample face is obtained. The thing by which that's integrated gives us the surface form.

“Of the wide measuring range, sensitive surface shape measurement is possible by a short time.”

concept of developement

The conventional measuring instrument and inspection machine (AFM, SEM, Phase-shift Interferomertry, etc.) setting detectivity of the height strong, and the range that measurement area becomes small.

The core system “CSM/CSYS”

the development concept of the examination for surface shape machine can measure measurement subject of big surface area at high detectivity exactly at short time.

and operate it fast and make the tester which can display right minute digital image data.

The surface defect being related with the change of the height of the surface shape function

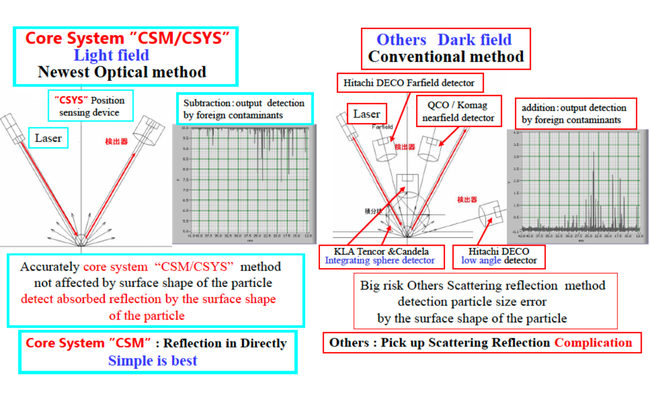

Comparison with other system

DOWNLOAD THE file

If you are interested in this product, please do not hesitate to contact with us.